Agri Pipes & Fittings

PIPES FOR AGRICULTURE

Airwin offers an extensive range of agriculture PVC-U pressure pipes and fittings. These pipes and fittings are designed specifically for varied pressure and gravity flow applications in agriculture, irrigation, swimming pool applications, and domestic water supply including potable water supply.

Airwin agriculture PVC-U pressure pipes offer significant advantages. They are light in weight, easy for transportation and installation, and have a high flow rate. High resistance to chemicals and corrosion ensures an extended product life.

Stringent quality assurance approach across all stages of manufacturing gives the product a high degree of reliability, making Airwin agriculture PVC pipes a preferred choice for farmers, government institutions, domestic and commercial establishments and quality conscious people across the country.

Our agriculture pipes and fittings are recommended for water temperatures ranging from 1°C to 45°C. As the usage temperature increases, the strength of the pipes reduces along with the working pressure.Occasional rise in temperatures in the summer with concurrent reduction in temperature during nights has no adverse effect on the working pressure of pipes.

Airwin agriculture PVC-U pipes are manufactured in a wide range of sizes and pressure classes conforming to standard IS 4985:2000. These agriculture water pipes are available in sizes ranging from 20 to 400 mm in different pressure classes. They are available in two types of joints, Selfit (solvent cement joint) and Ringfit (rubber ring join

Features & Benefits

Smooth inner walls minimize frictional losses and scaling due to precipitation

In ringfit pipe deflection of pipes due to soil shifting and land contour can be easily accommodated up to 2 degrees per joint

Increased product life as these pipes are free from weaknesses caused by scaling , rusting, weathering and chemical action

Ringfit pipelines can be tested and put to immediate use after jointing as there is no curation period needed

All Weather Jointing

Non-reactive to acids, alkalis, effluents, salt, and minerals

Application

Airwin CPVC pipes are suitable for hot and cold water distribution systems for indoor and outdoor applications. Note: Not suitable for compressed air and gases.

Irrigation schemes

Potable water supply lines

Biogas plants

Rising main and distributing lines

Main lines for sprinkler and drip irrigation

Household

Technical Details

JOINTING

For Ringfit Pipes :

1. Cleaning : The surface dirt, grease or moisture must be removed with a clean dry cloth.

2. Rubber Ring fitment : Take rubber ring & clean for surface dirt of any & insert in pipe groove by hand.

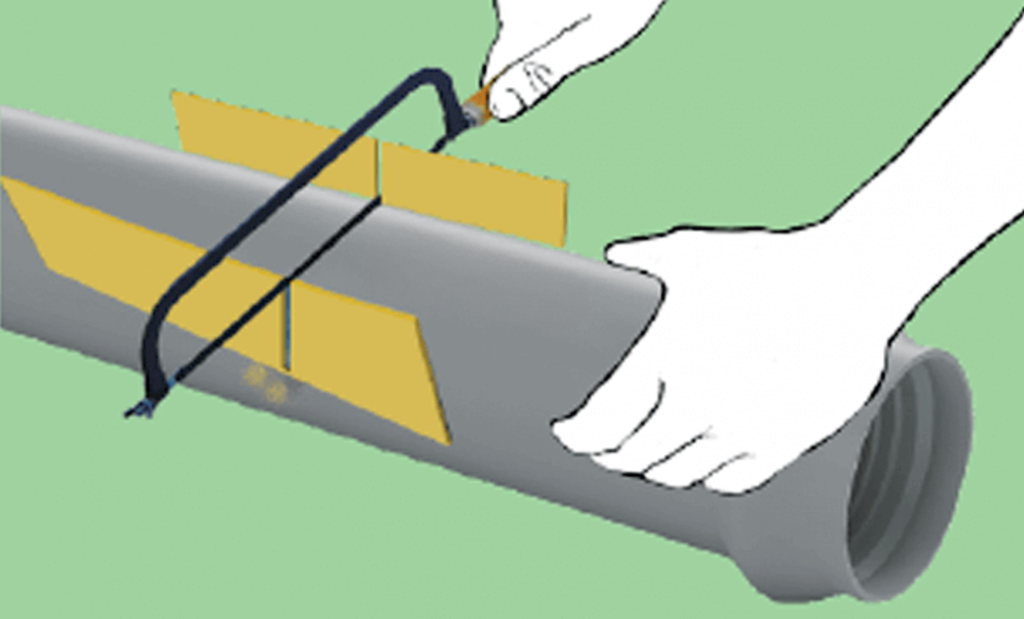

3. Cutting : The pipe must be cut in a square shape. The base of the fitting socket needs a rubber ring to seal it, since an angled cut may result in leakage.

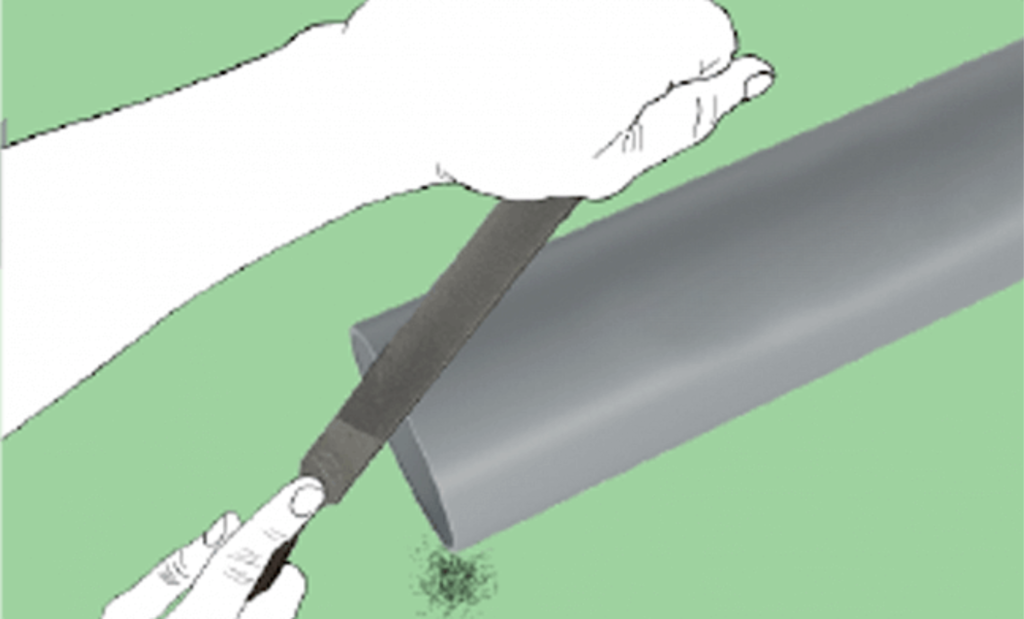

4. Chamfering and cleaning : The surface dirt, grease or moisture must be removed with a clean dry cloth. A 10° – 15° chamfer must be made at the end of the pipe.

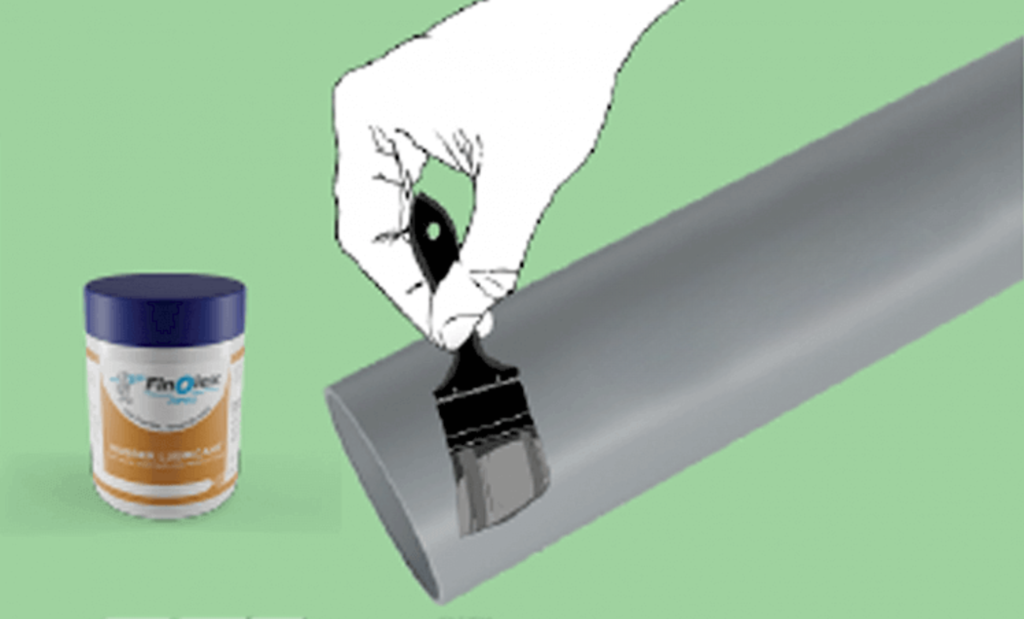

5. Lubricant application : Apply even layer of lubricant on rubber ring and outer diameter of pipe prior to insertion.

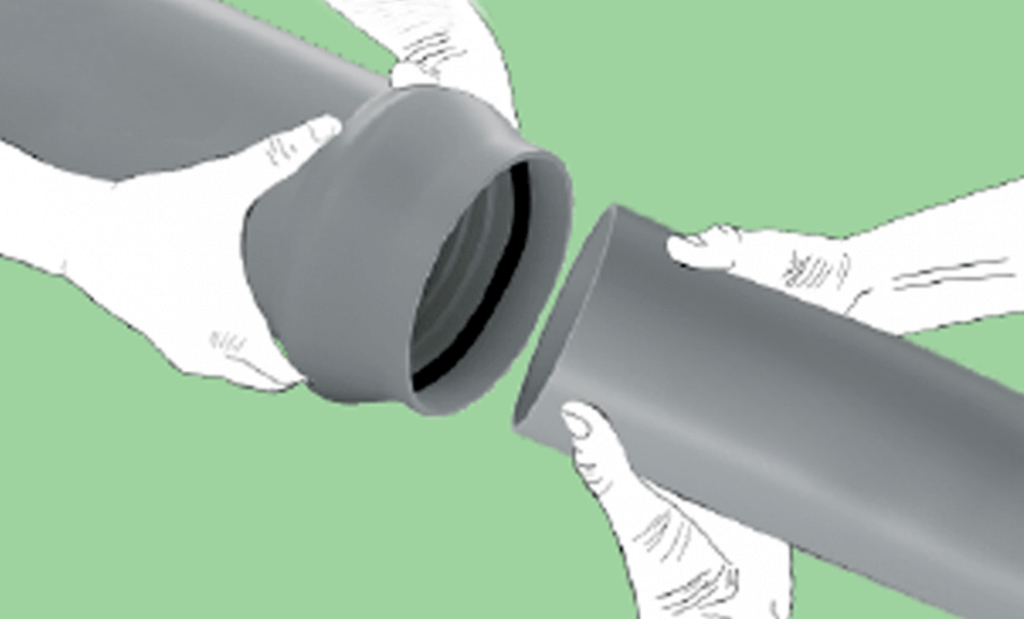

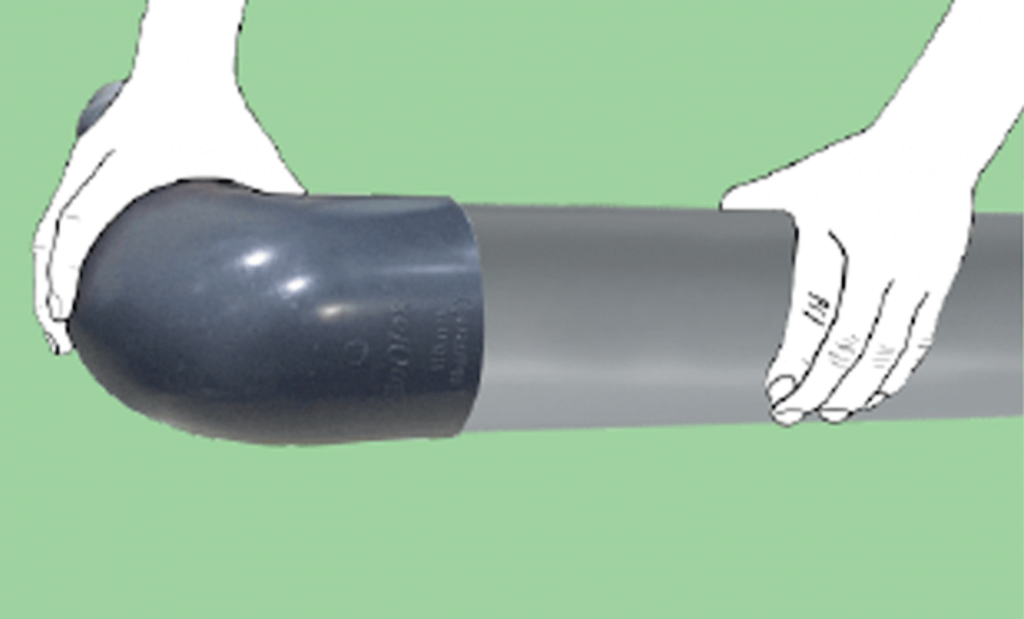

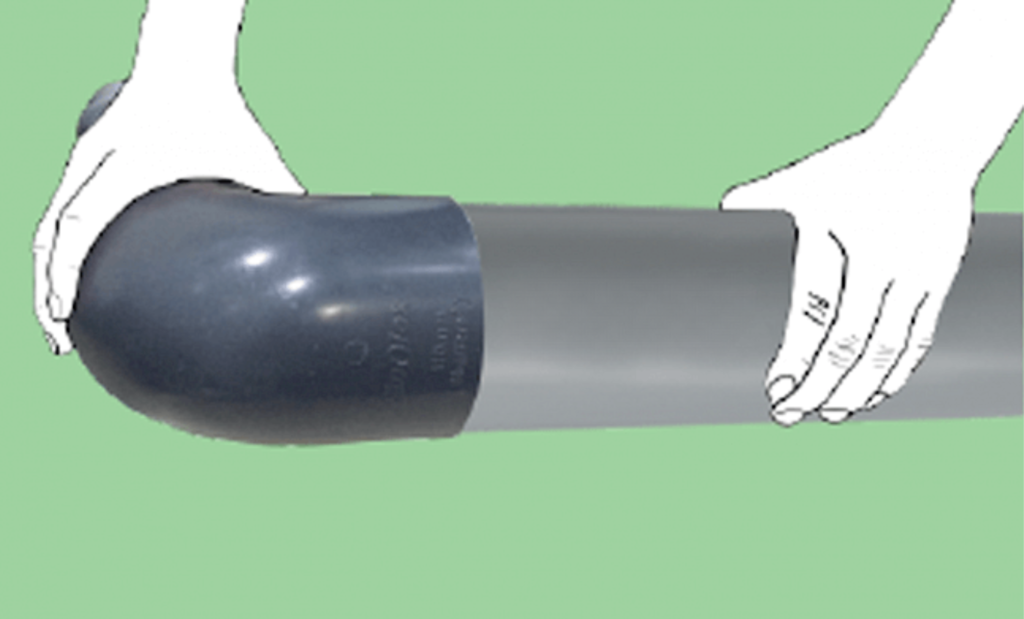

6. Assembly : Push the pipe in integrated ring socket till end.

For Selfit Pipes & Fittings:

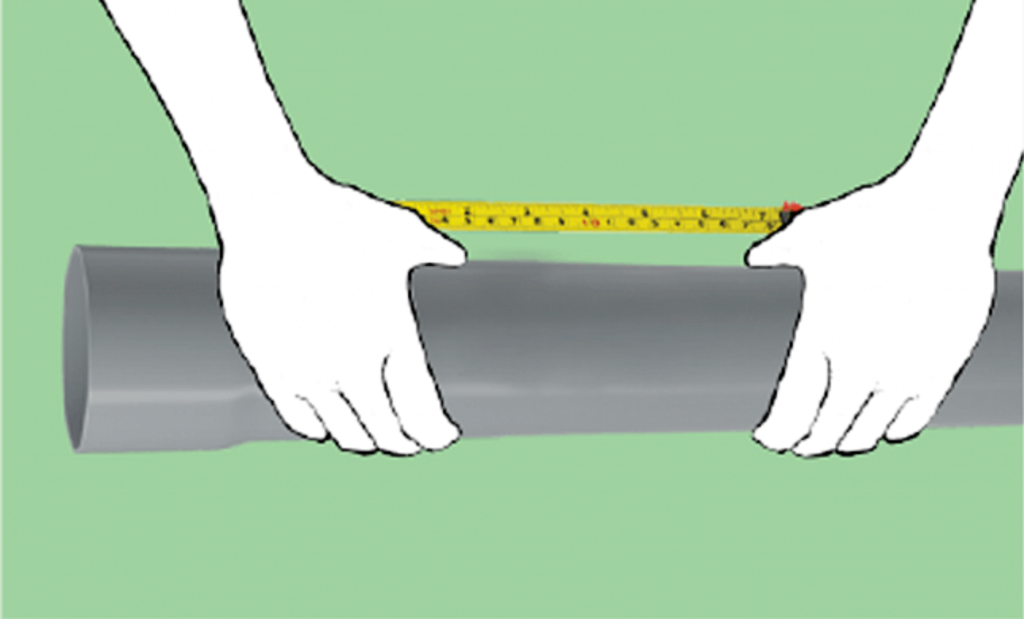

1. Measuring : Measure the required length of pipe and marking done.

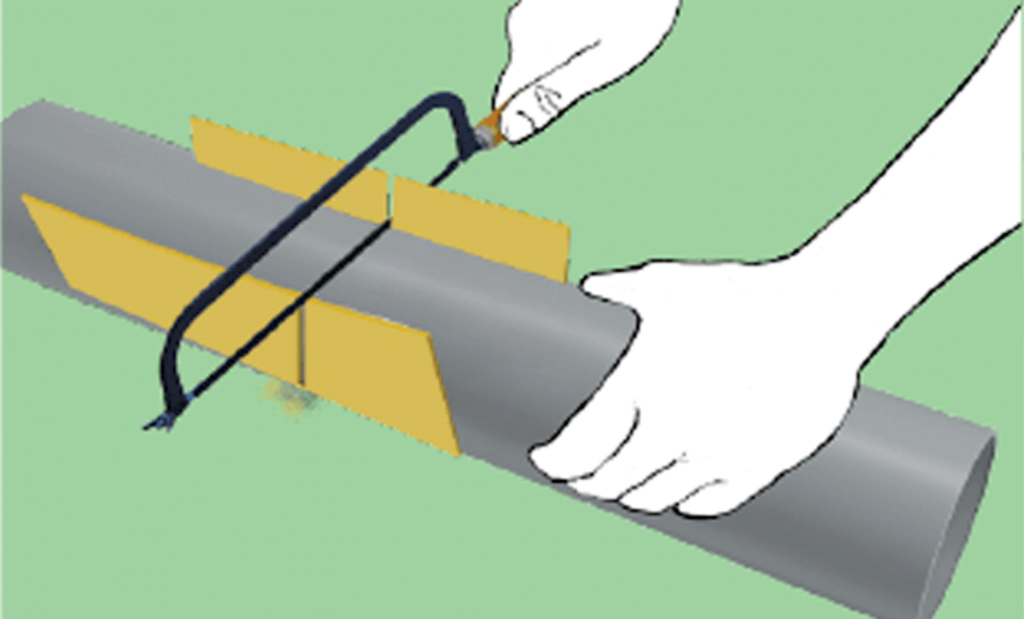

2. Cutting : The pipe must be cut in a square shape. The base of the fitting socket needs a rubber ring to seal it, since an angled cut may result in leakage.

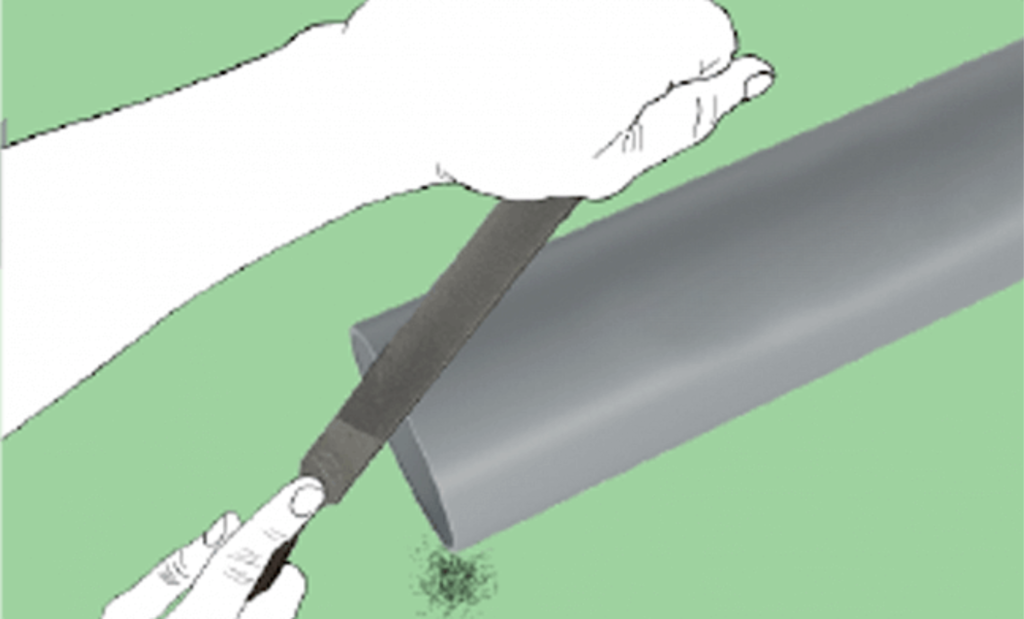

3. Deburring & Chamfering : All the burr must be removed from the inside and outside of the pipe with a knife, file or de-burring tool. A 10° – 15° chamfer must be made at the end of the pipe.

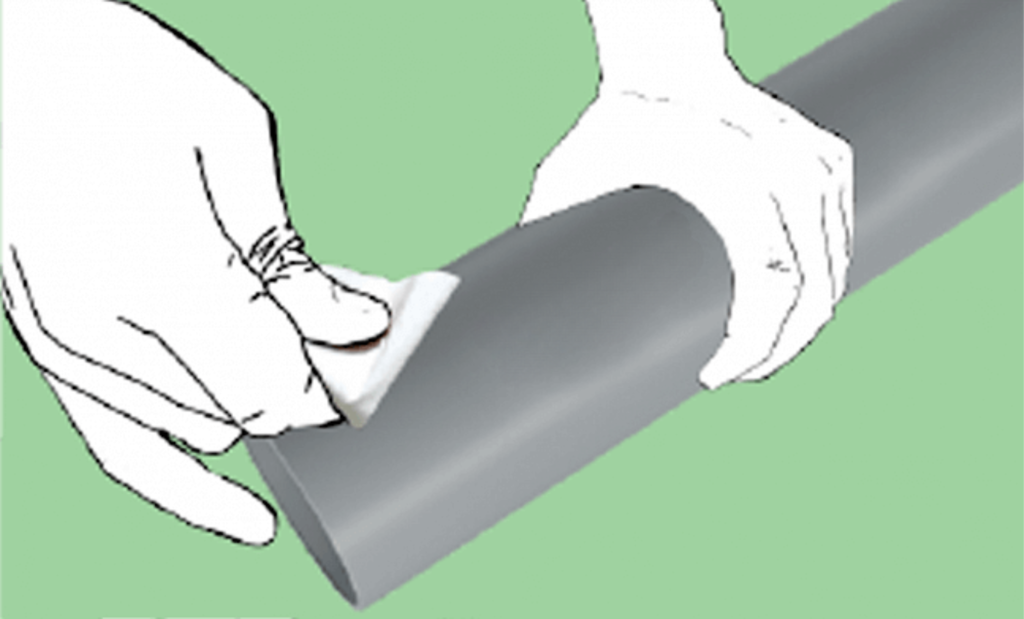

4. Cleaning : The surface dirt, grease or moisture must be removed with a clean dry cloth.

5. Check Dry Fit : Using light pressure, the pipe should be inserted one third to half the way into the socket. Note that pipes and fittings that are too tight or too loose should not be used.

6. Solvent Cement Application : An even layer of cement should be applied to the outer side of the pipe and a medium layer of the solvent cement to the inside of a fitting.

7. Assembly : Join the pipe and fitting socket till in contact with the socket bottom. Hold the pipe and fitting together until the pipe does not retract. The excess cement can be removed from the exterior surface of the pipe and fitting. A properly made joint will show a continuous bead of cement around the perimeter of the pipe and fitting.

Technical Details

| Outside diameter of pipe (mm) | Outside diameter of pipe (inches) | Approx No. of Joints/Ltr. of Airwin Solvent Cement | |||

| 20 | ½” | 300 | |||

| 25 | ¾” | 250 | |||

| 32 | 1″ | 225 | |||

| 40 | 11/4” | 175 | |||

| 50 | 11/2” | 130 | |||

| 63 | 2” | 125 | |||

| 75 | 21/2” | 100 | |||

| 90 | 3” | 75 | |||

| 110 | 4” | 50 | |||

| 140 | 5” | 35 | |||

| 160 | 6″ | 28 | |||

| 180 | 7” | 25 | |||

| 200 | 8” | 15 | |||

| 225 | 9” | 12 | |||

| 250 | 10” | 9 | |||

| 280 | 11” | 7 | |||

| 315 | 12” | 5 | |||

| 355 | 14” | 3 | |||

| 400 | 16” | 2 |